+

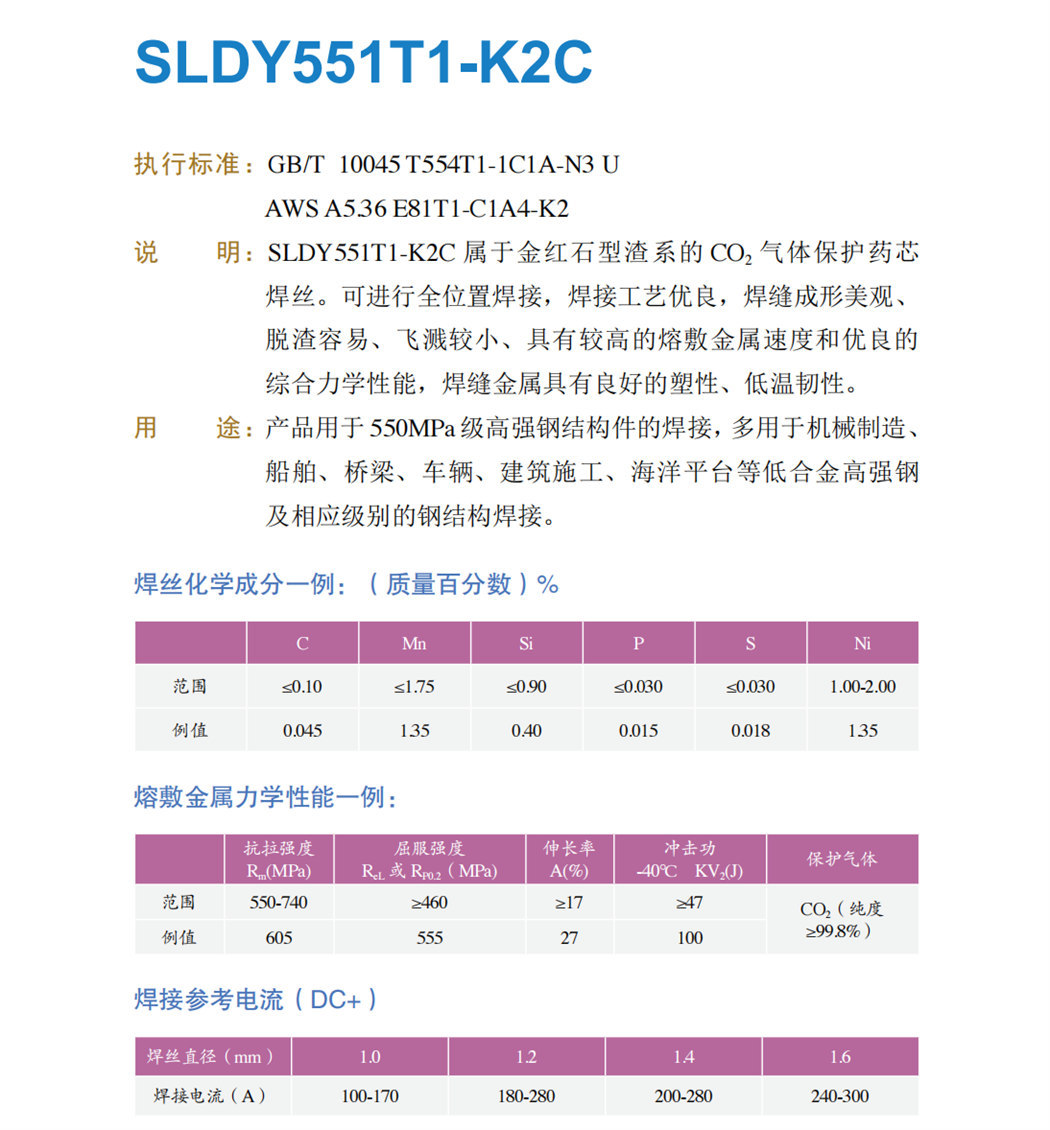

SLDY551T1-K2C气体保护药芯焊丝

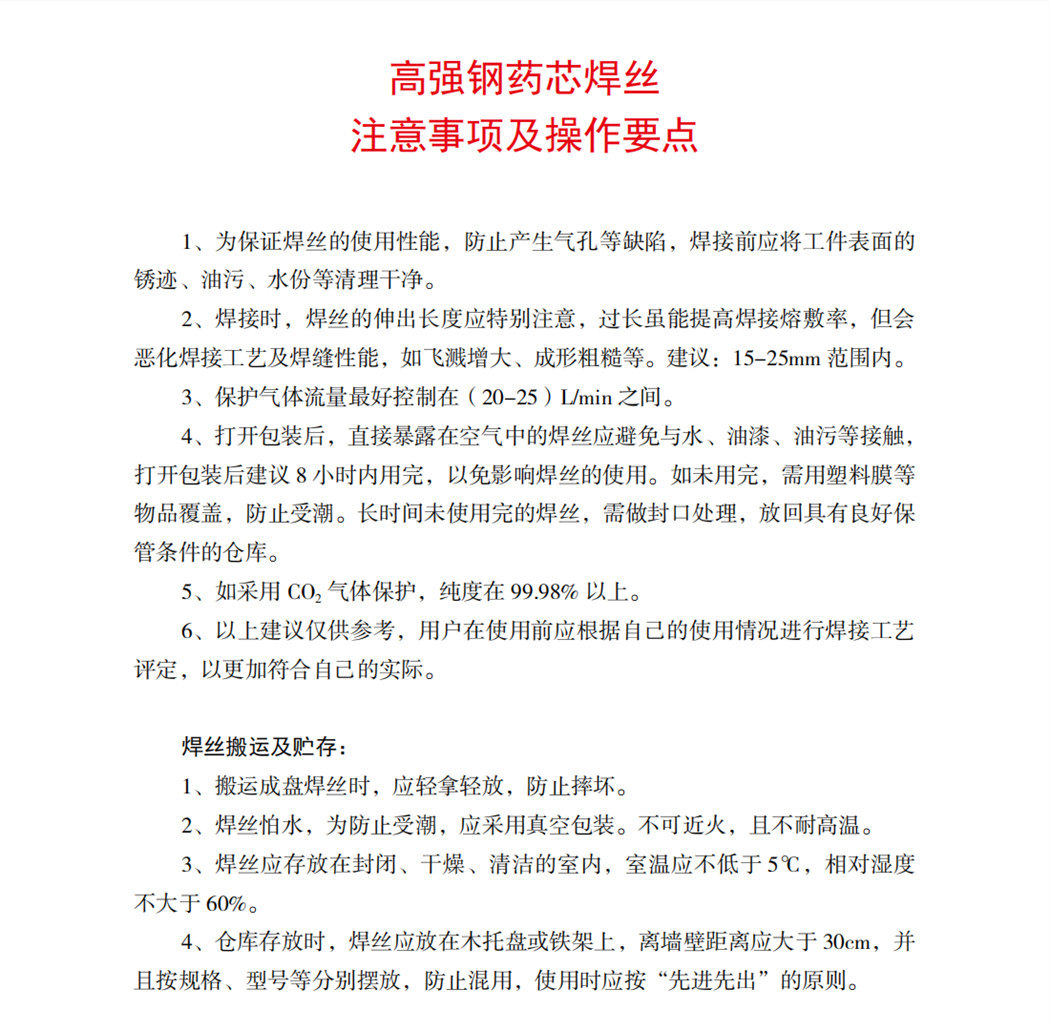

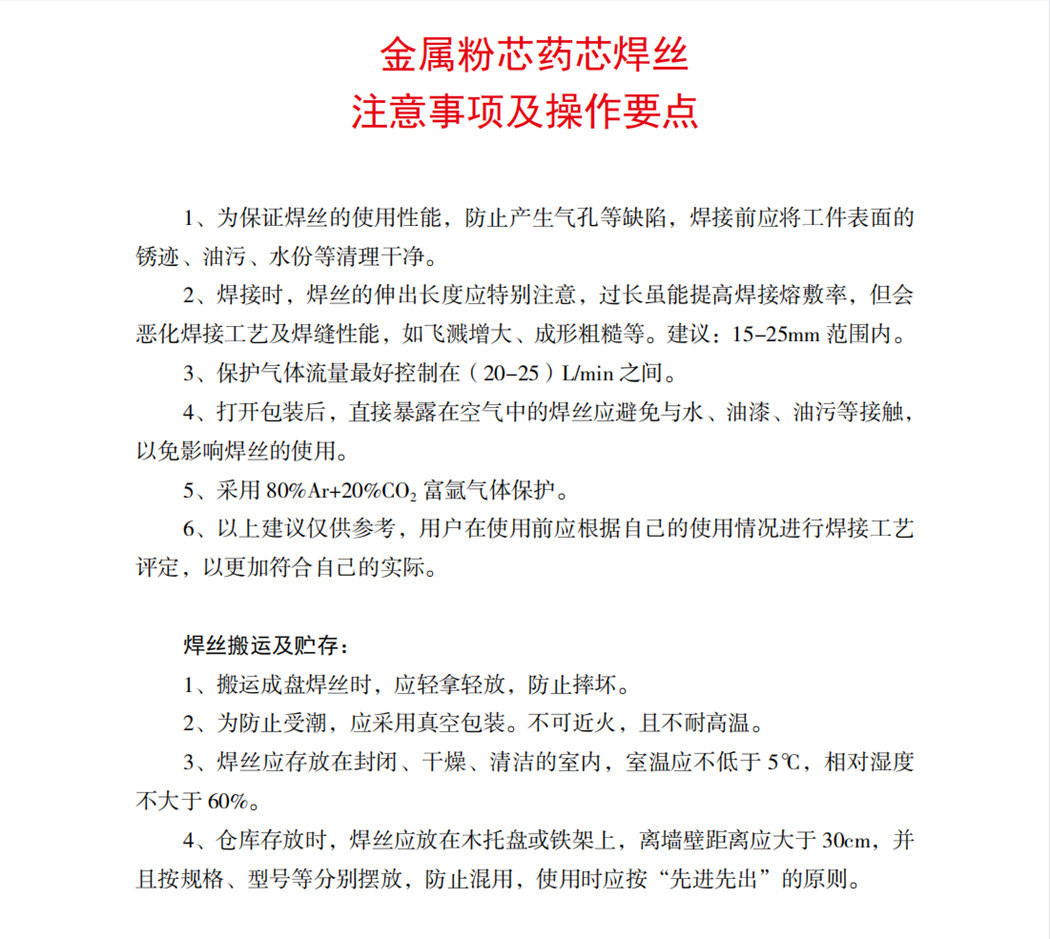

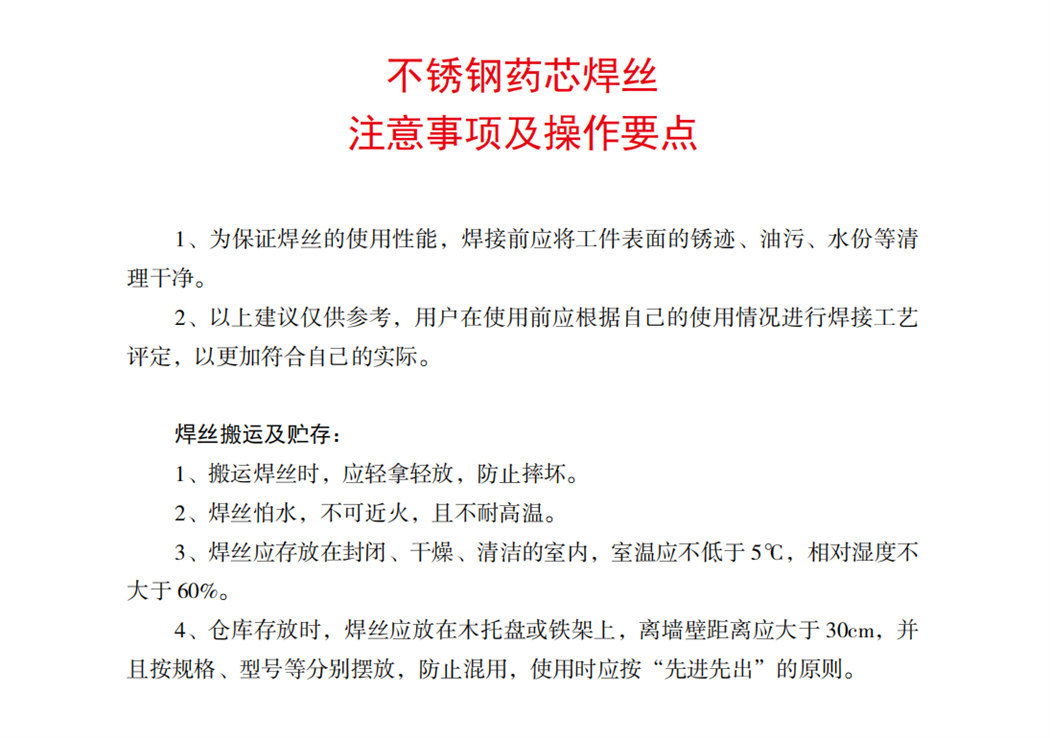

1、为保证焊丝的使用性能,防止产生气孔等缺陷,焊接前应将工件表面的锈迹、油污、水份等清理干净。

Key words:

Product category:

Related products

1SLDSJ112 is a fluorine alkali alkaline sintered flux, with gray white circular particles, particle size of 10-60 mesh, and alkalinity of 2.6. It is made from powders such as silicate, carbonate, fluoride, metal oxide, and iron alloy through processes such as balling, low-temperature drying, and high-temperature sintering. The performance of the flux can replace Lincoln's 801 flux in the United States, with beautiful weld formation, smooth surface, no slag inclusion, porosity, and cracks, and good welding process.

SLDSJ601 is an alkaline sintered flux for submerged arc welding of stainless steel and heat-resistant steel, with a particle size of 3.0-0.28mm (10-60 mesh). It is used for direct current welding and welding to the positive rod. Stable arc combustion, easy slag removal, beautiful weld formation, and excellent intergranular corrosion resistance of weld metal.

SLDSJ609 is a fluorine alkali type high alkalinity low hydrogen sintered flux with an alkalinity of about 2.2. The flux is circular particles with a particle size of 2.0-0.28mm (10-60 mesh). Adopting DC power supply, welding wire connected to positive rod, excellent welding process performance, stable arc, excellent slag removal performance, and beautiful welding formation. The weld seam has excellent crack resistance and high low-temperature impact toughness.

SLDSJ603W is a fluorine-alkali alkaline (B ≈ 2.0) sintered flux, with spherical particles and particle size of 2.0-0.28mm (10-60 mesh). It is used for both AC and DC purposes, with stable arc stability, good high-temperature slag removal performance, and strong resistance to porosity. The flux contains deoxidizers and alloying agents, and the weld seam has excellent low-temperature impact toughness.

Contact Us For Quotation

Online message

Bottom link

Contact us

Add: Shiheng Town, Feicheng City, Shandong Province

Contact number: 86-0538-3660400

Enterprise Email: 001@sldhc.com